Welcome to Conelec Systems Private Limited

- Mon - Sat: 8.00 am - 7.00 pm

About Conelec Systems Private Limited

We're Partner of Your Innovations

“With technological advancements and up gradation present day power distribution requires specialized experience and products quality to meet the vital requirements in the varied fields of electrical engineering”.

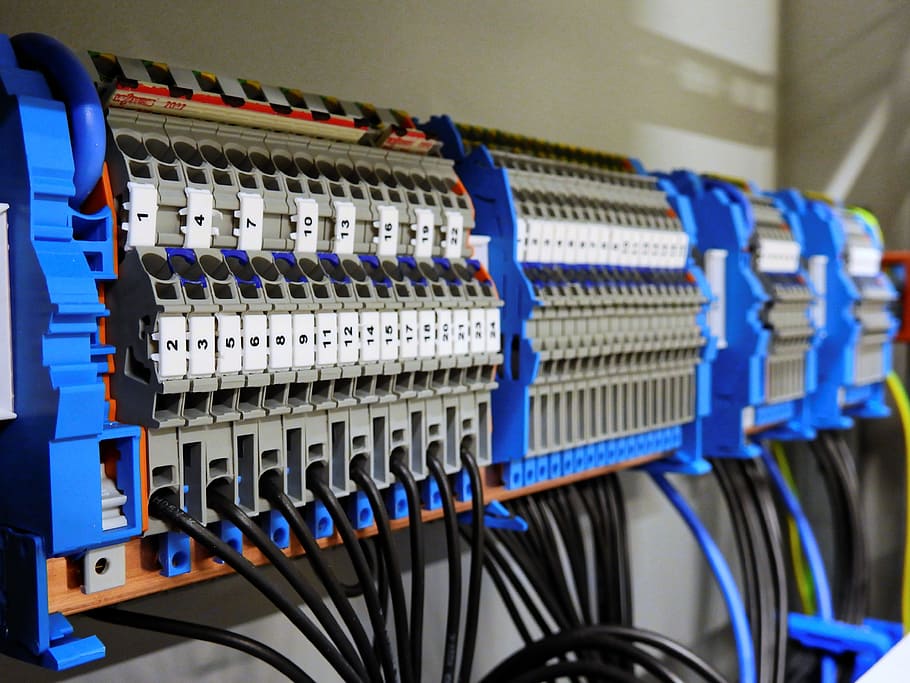

Conelec Systems Private Limited established more than a decades ago with its dedicated engineering manpower and distinctive experience serve several industries with product and services ranging from design and manufacturing of electrical switchboard to substation and internal electrification over and above specializations in automation and internal & external lighting with unique feature of facade lighting The system and services offered by CONELEC are well adapted for hot, dusty and humid Indian conditions and are as per Indian and International standards.

The quality format of the company has been established in compliance with quality management systems. In view of the underline the quality the system is monitored by Mr. Vikas Vij (Director) who is a an Electrical Engineer and Management qualified and believes in continuous quality development and growth. With a simple motto of “Honesty, Hard work and Dedication”, we at CONELEC are determined to

serve the Industry with an attempt to innovative development for progress of economic and industrial activities for benefit of the customers at large.

Active Clients

Projects Completed

Glorious Years

Professional team

Better Solutions & Services at your Fingertips

PROFILE OF

MANUFACTURING FACILITIES AT CONELEC

“Bechtel India, BHEL, Military Engineering Services are to name a few in the long list of CONELEC esteemed clients where electrical switchboards have been supplied.

With a track record that speaks for itself and a distinguished quality system CONELEC today enjoys a name of prominence in the field of electrical engineering.

Modern shop practices, extensive tooling, Autocad designing are a few of the features at CONELEC which ensures highest regard for quality, accuracy and ease of interchangeability in service and maintenance.

Today, CONELEC designs, manufactures and markets custom built switch gear and control panels for industries which include Power, Chemical Steel, Textile to Paper and the panels designed are well suited for Indian conditions. For example the bus bars are specially sleeved and insulated with supports of glass reinforced polyester with built in anti tracking barriers . CONELEC bus bars have

been successfully type tested for short circuit of 50 KA at CPRI, Bhopal and confirms to IS-8623. The painting is done after pre treatment with seven tank process. The degree of protection for ingress is designed for IP-54 and above where specifically required.

CONELEC with its vast experience can now design and manufacture LT Power and Control gear for Industries to fulfill their exact requirements and support it with prompt, reliable and economical customer service.

SALIENT FEATURES OF CONELEC

MAKE PCC/ MCC

Our PCC/MCC and Bus Duct have been successfully tested at Central Power Research Institute, Bhopal for “Verification of short circuit strength” at 1 second as per IS: 8623. This proves quality of Bus Bar supports and their required spacing.

We use electrolytic grades of Aluminium Bus Bar type IE-94-E/ Electrolytic grades of copper which is duly tested for electrical straight and mechanical strength.

We use non-hygroscopic SMC supports for Bus Bar for better mechanical and electrical strength and in order to ensure capability to withstand specified fault level.

Panels are totally enclosed, dust vermine proof, fully compartmentalized, cubical design and modular construction The covers and doors are very well gasket with neoprene rubber gasket so as to obtain dust proof enclosure.

The Panels are manufactured with separate Bus Bar chamber isolated from unit feeder chambers and cable Alleys. This provides extra safety for working personnel.

The Panels are made out of 2mm thick CRCA sheet steel for robust construction . The doors provided with concealed hinges for better aesthetic appearance.

All sheet metal work is carried out by means of Hydraulics Shear and Hydraulics Press Brake of reputed make, thereby obtaining desired accuracy.

We have standardized and size of panel compartment, Bus Bar Chamber, Cable Alley depending upon switchgear. This result in obtaining much better quality and accuracy.

The panel are treated for de-greasing, de-rusting , phosphating ,and passivating by adopting Seven Tank process as per the Indian Standard Specification before Panel are painted with 2 coats of Zinc Chromate as primer and 2 final coats of stove enamel paint of required shade as per IS.

The painted of panel is carried out in Painting Booth / Powder Coating in Chamber having dust free atmosphere and then baked in Oven specially designed for the size of Panels.

We’re here to help to grow your business.

Looking for the Best IT Business Solutions?

Conelec Systems Private Limited is a dedicated engineering manpower and distinctive experience serve several industries with product and services …….

© All Copyright 2024 Conelec Services Private Limited.